Commits on Source (4)

-

Fabrice Salvaire authored90130356

-

Fabrice Salvaire authored0fe2d84a

-

Fabrice Salvaire authoreddd120bc7

-

Fabrice Salvaire authoredddede908

.gitignore

0 → 100644

datasheets/331k1.pdf

0 → 100644

File added

datasheets/SINGER 331K104.pdf

0 → 100644

File added

50.9 KiB

69.8 KiB

45.7 KiB

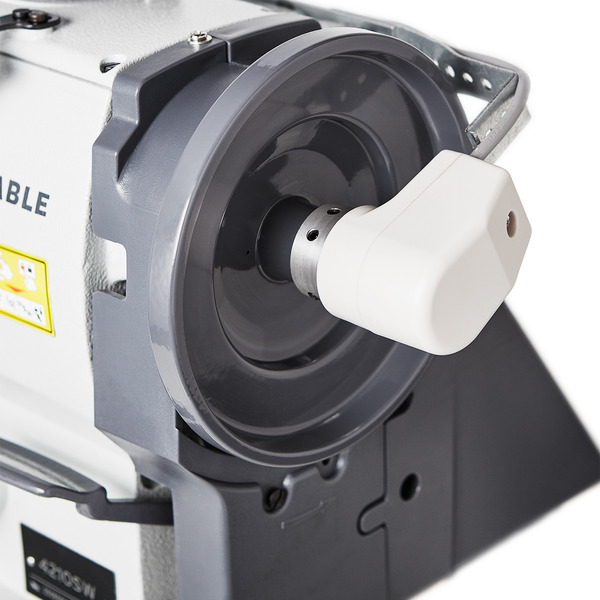

photos/singer-331k104/20210422_210311.jpg

0 → 100644

2.86 MiB

photos/singer-331k104/20210422_210317.jpg

0 → 100644

2.82 MiB

photos/singer-331k104/20210422_210321.jpg

0 → 100644

4.02 MiB

2.95 MiB